Fiber Reinforced Concrete

Our high performing polymer macro fibers offers the performance of steel fibers at lower dosage rates. The unique anchorage system of each macro synthetic fiber and the higher aspect ratio (length/diameter) allows for higher performance in the concrete matrix.

The macro synthetic fibers infuse the concrete with added levels of toughness, energy absorption and durability. In addition, macro-synthetic fibers provide an added measure of crack control without the risk of corrosion associated with steel.

- REPLACEMENT OF STEEL REINFORCEMENT

- SHRINKAGE AND CRACK CONTROL

- REDUCED SLAB THICKNESS

- FASTER PROJECT EXECUTION TIMES

- HUGE SAVINGS ON CAPITAL COSTS

Advantages of Using Fibers

EASY, SAFE AND COST-EFFECTIVE.

- Simply add the water-soluble bags or pucks directly into the ready mix trucks.

- Macro fibers compared to welded wire fabric or rebar, there is no lifting, cutting, chairing, tripping and scrapes.

- Lower labor costs.

- Saves construction time – quicker placing schedule.

- If a site requires, a Fibermesh® , Enduro®, and Novomesh® solution the fibers can be easily pumped.

- Finishes easily and smoothly with common tools.

- Requires no minimum amount of concrete cover.

- Technical support available to provide designed solutions.

- Products test and proven independently to ASTM and European standards.

Synthetic micro fibers:

“secondary” reinforcement; shorter and finer strands, plastic shrinkage crack control only. They can be monofilament or fibrillated (0.9Kgs/M3) .

Synthetic macro fibers

longer and coarser strands, shrinkage crack control and replacement of steel reinforcement. Dosage rates should be calculated by engineering requirements and equations 1.8 to 12 Kgs/M3 .

Steel fibers

longer and coarser pieces, extended structural applications. Dosage rates should be calculated by engineering requirements and equations (15-100 pcy)- Upto 60 kgs/M3

DRAGX

Nanocomposite Surface Treatment for Pipelines Anti-fouling, anti-corrosive and maintenance reducing superthin surface treatment for internal surfaces. Dragx can be a game changing solution to rehabilitate in situ pipelines and increase throughput drastically.

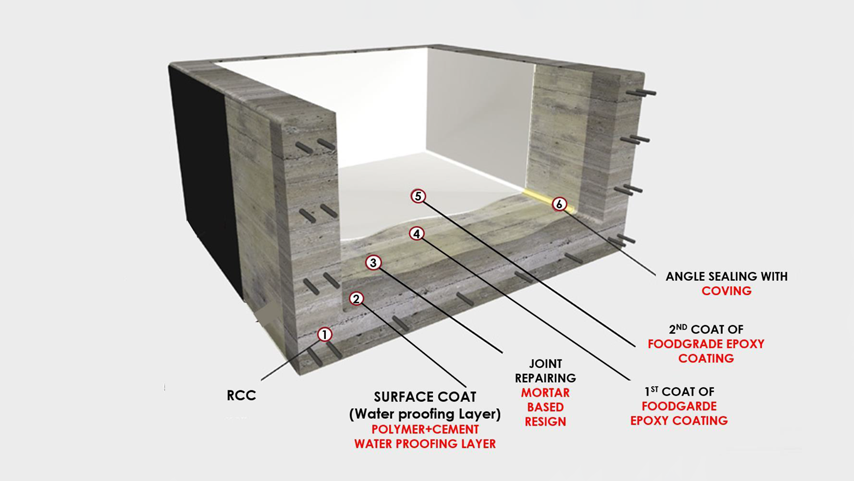

water storage tank treatment

High Performance Waterproof Protective And Food Grade Epoxy Lining System For Water Reservoirs

A high-performance epoxy based waterproofing coating system in place of cement plaster or cement mortar lining in the water reservoirs. In-situ application on casted concrete surface.

Base Bonding Layer of Polymer modified cementitious Waterproof Coat Advantages- Penetrates cracks and pores and Sealing micro damages like hair cracks, joints, micro porosity, holes, dents etc.

ADVANTAGES

- Superior water proofing properties due to multiple hybrid layers.

- CFTRI approved food grade epoxy (USFDA- 21CFR 175-300) for potable water

- Excellent chemical resistance against chlorine and other dissolved salts

- High abrasion, erosion resistance and excellent bonding with base surface

- Long term anti-fungal, anti-bacterial properties

- Highly impervious membrane formation

- Crack and debonding resistance

- Maintains water quality for longer period of time.

- Low VOC and completely solvent free

- Easy to apply and easy to maintain

- Maintains excellent aesthetics looks